APPLICATIONS

- Service brake

- Safety brake

- Emergency brake

ORIGINAL EQUIPMENT

- Zinc coated steel structure - epoxy resin painting - RAL 3000 final colouring.

- Stainless steel pins, self lubricating bushes on main joints

- Asbestos free linings, bonded to easy-to-replace plates.

- Friction coefficient µ =0,4

- Braking torque scale indicator

OPERATION

- The disc brake MATEC MD are negative brakes (spring loaded).

- The braking force is obtained by means of a spring that, through a suitable system of levers, transmits its amplified action to the braking pads, where the linings are fitted.

- An electro-hydraulic or pneumatic thrustor makes an apposite force to the spring load, causing the pads to open, therefore the brake to release.

- The braking force given by the linings against the disk can be modulated by adjusting the spring. (see standard features).

- Braking torque changes depending on braking force modulation.

OPTIONALS

- Automatic wear compensation RG. Linings max wear indicator, fitted on rod FCU.

- Open brake indicator, either fitted on thrustor or on spring set ( to be specified) FCA

- Brake manual opening lever LSM.

THRUSTOR TYPES

- MATEC type "M" electrohydraulic

- EMG type "ELDRO" electrohydraulic

- EMG type "ELTMA" electrohydraulic

- Pneumatic (upon request)

BRAKE SELECTION DATA

- Type of application

- Stops per hour

- Required braking torque

- Disc diameter (30 mm. Standard thickness)

- Required voltage (standard 230/400 V. - Hz. 50) or air pressure supply

- Required optional

DISC BRAKE TYPES

- MD= Disc brake for thrustor MATEC "M" - EMG "Eldro" - EMG "Eltma"

- 1-2-3= type of brake

- diameter = disc diameter (30 mm.standard tickness)

- RG= automatic wear compensation

- FCU= linings max wear indicator

- FCA= open brake indicator

- LSM= brake manual opening lever

- DX= right hand layout

- SX= left hand layout

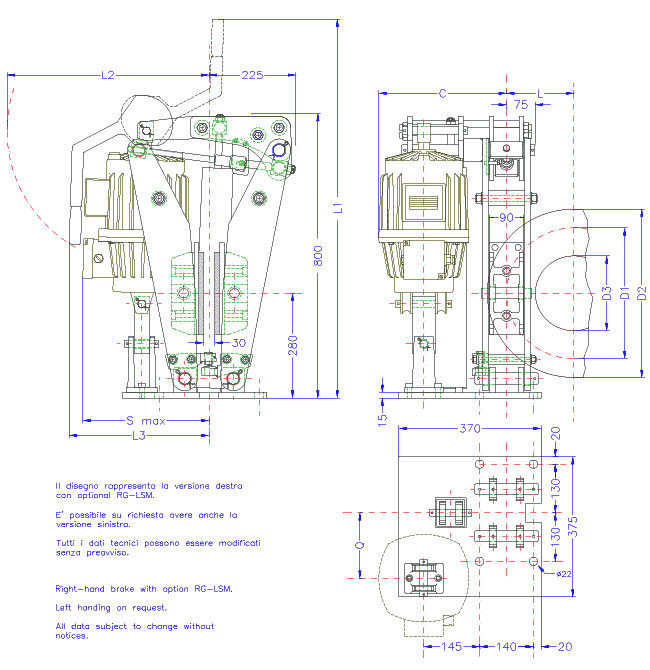

| MD2 Dimensioni in mm |

Servofreno tipo | ||||||||

| M60/50 ELDRO Ed 50/6 ANTEC TH-506 |

M80/60 ELDRO Ed 121/6 ANTEC TH-1306 |

M200/60 ELDRO Ed 201/6 ANTEC TH-2006 |

|||||||

| Ø D2 | Ø D1 | Ø D3 | L | S max | M max | S max | M max | S max | M max |

| 450 | 350 | 200 | 175 | 327 | 1350 | 348 | 2700 | 377 | 4500 |

| 500 | 400 | 250 | 200 | 327 | 1500 | 348 | 3000 | 377 | 5000 |

| 560 | 460 | 310 | 230 | 327 | 1700 | 348 | 3400 | 377 | 5700 |

| 630 | 530 | 380 | 265 | 327 | 1850 | 348 | 3700 | 377 | 6200 |

| 710 | 610 | 460 | 305 | 327 | 2100 | 348 | 4200 | 377 | 7000 |

| C=316 | C=332 | C=354 | |||||||

| L1=1088 | L1=1020 | L1=1276 | |||||||

| L2=540 | L2=542 | L2=746 | |||||||

| L3=358 | L3=371 | L3=413 | |||||||

| Q=175 | Q=175 | Q=195 | |||||||

Scostamento della guarnizione dal disco = 1,1

Mmax = coppia frenante statica in Nm per µ=0,4