- Cranes buffers according to accident prevention rules.

- Pre-studied structure able to permit automatic choice and dimensions for every buffer.

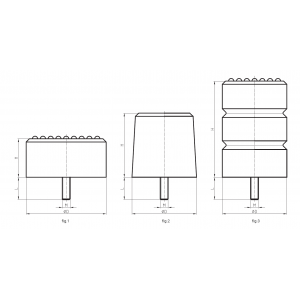

- Steel structure with tubes having slide in guide. The structure has an external and an internal sandblasting before the spray phosphating.

- Elastic groups in special rubber produced with particular mixtures preventing the aging and alternated to steel disks separators

- Mechanical safety factor referred to the maximum declared load= 1,75

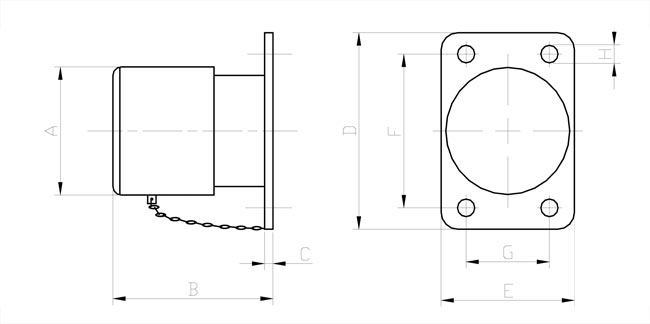

- Safety chain and fastening of shackles in chromate or zincked steel.

- Pre-stressed locking by a screw-bolt and auto-block nut.

- Crane Buffers “E” design allows to modify their stroke till reach stroke of Buffers “E-CD”; more over crane buffers “E” design allows to decrease (with same stroke) the load stated in the table.

In this way allows to obtain for each models a different Energy Capacity in function of stroke on load, giving an optimization of the Buffers for each different appliance. - To decrease the load can request from time to time indicating the load necessary or considering values valid total length of the bumper chosen.

To increase running from the values of table types "E", the total length of the desired buffer (in mm.) will be equal to:

TOTAL LENGTH OF BUFFER TAKEN INTO CONSIDERATION (in mm.) + TWICE THE EXTRA STROKE REQUEST (in mm.) + 1 / 3 of the TOTAL STROKE REQUEST

| MODEL | Stroke mm |

Load Kg | Energy Kgm |

A | B | C | D | E | F | G | H |

| E525 | 70 | 15.000 | 525 | 168 | 245 | 10 | 230 | 200 | 175 | 145 | 19 |

| E900 | 75 | 25.000 | 900 | 194 | 267 | 12 | 310 | 260 | 260 | 210 | 21 |

| E1750 | 90 | 40.000 | 1.750 | 245 | 324 | 14 | 360 | 310 | 300 | 250 | 24 |

| E2250 | 95 | 50.000 | 2.250 | 273 | 328 | 18 | 410 | 350 | 340 | 280 | 26 |

| E3250 | 105 | 65.000 | 3.250 | 324 | 378 | 18 | 410 | 350 | 340 | 280 | 26 |

| E525-CD | 140 | 15.000 | 1.050 | 168 | 435 | 10 | 230 | 200 | 175 | 145 | 19 |

| E900-CD | 150 | 25.000 | 1.800 | 194 | 472 | 12 | 310 | 260 | 260 | 210 | 21 |

| E1750-CD | 180 | 40.000 | 3.500 | 245 | 550 | 14 | 360 | 310 | 300 | 250 | 24 |

| E2250-CD | 190 | 50.000 | 4.500 | 273 | 603 | 18 | 410 | 350 | 340 | 280 | 26 |

| E3250-CD | 210 | 65.000 | 6.500 | 324 | 602 | 18 | 410 | 350 | 340 | 280 | 26 |

Quota B ± 5%

Temperature standard di utilizzo -10°C + 40°C

Possibilità di fornire modelli con temperature di utilizzo -40°C +90°C